Digital printing is transforming packaging by making customization affordable and easy. It’s ideal for brands that need unique packaging at a lower cost.

Digital printing is transforming packaging by making customization affordable and easy. It’s ideal for brands that need unique packaging at a lower cost. Digital printing1 makes it possible for brands to customize packaging at a lower cost, especially for small runs. It reduces setup costs and allows quick updates to designs without expensive reprints.

Let's explore how digital printing offers cost-effective solutions for businesses looking for flexibility and customization, especially for small batches.

How Can Digital Printing Help Brands Achieve More Cost-Effective Customization?

Digital printing offers the flexibility brands need to meet consumer demand for unique packaging. It removes expensive setup steps and lowers the overall cost for customization.

By cutting out the need for printing plates, digital printing lowers the cost of customization. Brands can quickly adapt their packaging designs without adding extra expenses for small batches.

Direct Digital Printing Saves Costs

Traditional printing requires creating physical plates, which adds costs. With digital printing, designs are directly transferred to the packaging material, making it quicker and cheaper. No plates are needed, which saves both time and money.

Flexibility for Small Batches

Digital printing makes it possible for brands to customize packaging at a lower cost, especially for small runs. It reduces setup costs and allows quick updates to designs without expensive reprints. Small runs2 refer to producing smaller quantities of packaging without the high costs usually associated with traditional printing methods.

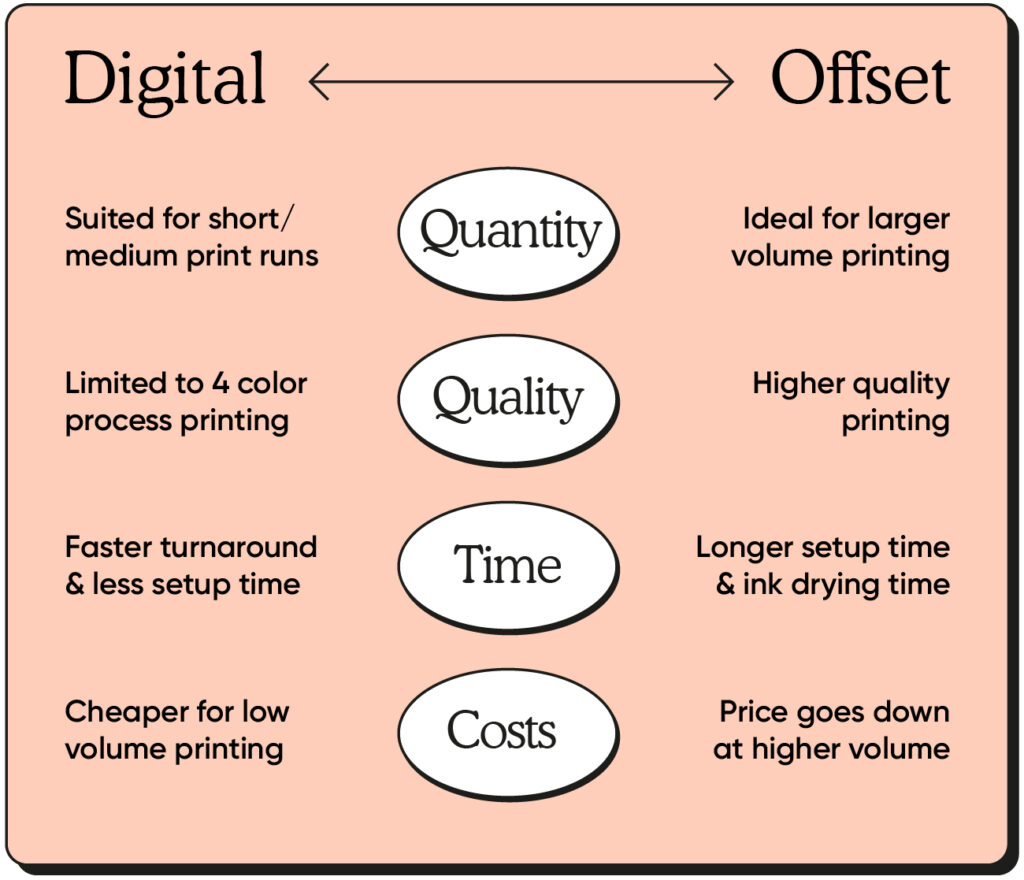

When we compare digital printing to traditional methods, digital printing stands out in many ways. # Traditional printing requires creating physical plates, which adds costs. With digital printing, designs are directly transferred to the packaging material, making it quicker and cheaper. No plates are needed, which saves both time and money. Flexography3 and gravure printing4 are traditional printing methods that require physical plates.

Additionally, they usually only make sense for large production runs, meaning smaller businesses are often left out.

Digital printing, on the other hand, eliminates the need for these expensive plates. This change reduces the initial costs. With digital printing, brands can print just what they need. This is especially helpful for smaller businesses or startups who need affordable solutions. Startups5 often face challenges with high upfront printing costs for traditional methods.

Brands can experiment with limited edition products or seasonal designs without committing to a large volume. This flexibility means they don’t have excess packaging sitting around. It’s a better way to control costs and inventory, especially when catering to niche markets or testing new products.

How does digital printing reduce upfront costs for small-batch production runs?

For smaller businesses, upfront costs can be a challenge. Digital printing lowers these costs, allowing small batches to be produced without high initial expenses.

Digital printing reduces upfront costs by eliminating the need for expensive printing plates. Brands can print only what they need, which is a great fit for small businesses with limited resources.

Small businesses often struggle with the high upfront costs of traditional printing methods. Creating printing plates can be expensive and doesn’t make sense for small production runs. That’s where digital printing steps in. It doesn’t require printing plates, which means the initial investment is much lower.

This makes it easier for smaller businesses to produce packaging in small quantities. Companies don’t have to worry about investing heavily upfront. Instead, they can print only what’s needed, which is more affordable and manageable.

Digital printing also supports on-demand printing, meaning businesses don’t need to produce large volumes at once. This flexibility helps brands better manage their inventory. They can print as needed, avoiding waste and reducing storage costs.

Comparison of Traditional vs. Digital Printing for Small Batches

| Feature | Traditional Printing | Digital Printing |

|---|---|---|

| Initial Setup Cost | High (plates required) | Low (no plates) |

| Volume Requirement | Large batches needed | Small batches allowed |

| Time for Setup | Time-consuming | Quick turnaround |

| Flexibility for Design | Low (plates need to be redone) | High (easy design changes) |

Why is digital printing considered more economical than traditional printing for smaller quantities?

Digital printing is cheaper for smaller quantities because it removes the need for plates. Without the high setup costs, businesses can produce packaging on a smaller scale at a lower price.

For small quantities, digital printing is more economical. It eliminates the need for printing plates and long setup times, which helps reduce costs for brands that only need small batches.

Digital Printing’s Cost Efficiency for Small Runs

Traditional printing methods like flexography and gravure require the creation of plates, which are expensive. This makes them cost-effective only for large runs. On the other hand, digital printing uses digital files, meaning there are no plates involved. This drastically reduces the cost for small-batch production.

Reducing Waste and Excess Inventory

One of the biggest advantages of digital printing is that it helps reduce waste. Brands don’t need to print more than they need. This means less unused inventory and fewer resources wasted. Businesses can print what’s needed and avoid stockpiling packaging they might not use. Inventory management6 plays a crucial role in reducing costs and waste.

Traditional printing methods like flexography and gravure printing are often better suited for large production runs due to the costs associated with creating plates. These methods are not economical for smaller quantities, as the initial investment in plates and setup time can make the cost per unit quite high.

With digital printing, these barriers are removed. The setup process is quick and cost-effective. This allows businesses to print only what they need without being forced to produce large volumes. It’s the perfect solution for companies with low order requirements or those that want to test new designs without committing to a large investment.

Furthermore, digital printing minimizes waste by allowing businesses to print just what is required. Brands don’t have to worry about overproduction, and they don’t need to store large amounts of unused packaging. This reduces both the financial and environmental impact of production.

What are the long-term cost benefits of digital printing for businesses with frequent design updates?

In industries with fast-paced design changes, digital printing offers long-term savings. It allows businesses to update their designs quickly without incurring high costs for reprints.

Digital printing is perfect for businesses with frequent design updates. It allows them to make changes easily and affordably, helping brands stay current without additional costs for reprints.

In fast-moving industries, frequent design changes are a must. Whether it’s to follow new trends, meet regulations, or refresh branding, businesses need a way to make these changes quickly. Traditional printing can make this challenging and expensive. Each design update often requires new printing plates, which adds cost and time to the process.

Digital printing is perfect for businesses with frequent design updates. It allows them to make changes easily and affordably, helping brands stay current without additional costs for reprints. Design updates7 are frequent in industries such as cannabis or e-cigarettes due to regulatory changes.

The ability to make design changes on demand means brands don’t have to worry about spending a lot of money on reprints or inventory. This flexibility is valuable, as it allows businesses to adapt to market trends without unnecessary financial strain. Brands can stay on top of consumer preferences and regulatory changes without being held back by costly traditional printing processes.

Conclusion

Digital printing offers a cost-effective and flexible solution for brands looking to customize packaging in small quantities. It's an excellent choice for businesses that need to update designs frequently and want to reduce upfront costs.

-

Learn more about the digital printing process and how it’s revolutionizing packaging for businesses. ↩

-

Discover how small runs benefit businesses with reduced production costs and flexibility. ↩

-

Understand how flexography printing compares to digital printing and its impact on cost. ↩

-

Learn about gravure printing and why it’s less cost-effective for small batches than digital printing. ↩

-

Learn how digital printing is a cost-effective option for small businesses and startups. ↩

-

Understand how digital printing minimizes excess packaging and waste through on-demand printing. ↩

-

Explore how digital printing helps industries with changing regulations by allowing quick and affordable design updates. ↩