What Are the Essential Requirements for Spout Pouch Manufacturing?

Spout pouch production can be challenging—poor sealing leads to product leaks, consumer dissatisfaction, and damaged brand reputation. Have you faced these costly issues? The essential requirements for manufacturing spout pouches include precise control of temperature and pressure, high-quality pouch-making and sealing equipment, and consistent quality management to ensure reliable pouch integrity. Understanding these essentials will […]

How Are Spouts Installed in Pouches?

Ensuring the proper installation of spouts in pouches is crucial for maintaining product integrity and customer satisfaction. A faulty installation can lead to leaks, contamination, and compromised product quality. Spouts are installed in pouches using techniques such as heat sealing and ultrasonic welding1. These methods ensure a secure and leak-proof attachment, preserving the product’s quality […]

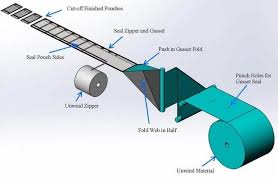

What Are the Key Steps in the Spout Pouch Production Process?

Finding reliable packaging solutions can be challenging, especially if you overlook critical production details, risking product leaks and customer dissatisfaction. The key steps in spout pouch production include careful material selection, precise manufacturing processes like printing and sealing, and stringent quality assurance to ensure durability and performance. Understanding these steps helps brands select the right […]

Can Digital Printing Optimize FMCG Supply Chains and Minimize Waste?

I see huge inventory piles and production delays. This problem causes financial stress. I want a solution that reduces waste and speeds up my supply chain. Yes, digital printing can optimize FMCG supply chains by allowing on-demand production, minimizing waste, and accelerating lead times. I have seen success with small and large brands alike, proving […]

Can Compliance Spark Digital Packaging Innovation?

I often notice confusion when brands confront strict packaging laws. They want to stand out but worry about legal penalties. These concerns can become powerful triggers for new methods. Yes, compliance can prompt advanced digital printing breakthroughs. It encourages swift changes, varied short runs, and bold designs that still align with FMCG industry mandates. In […]

Can Compliance Spark Digital Packaging Innovation?

Traditional packaging struggles with strict rules. Agitation: Non-compliance risks fines and product recalls. Traditional packaging compliance challenges and risks of non-compliance1. Compliance can spark digital packaging innovation by combining fast, precise printing with flexible design options. Digital technology meets strict regulations by ensuring accurate labeling and verifiable product information. It also offers quick response times, […]

Can Digital Printing Meet FMCG’s Green Demands?

Many FMCG brands want greener packaging. They worry about large inventories and environmental regulations. I see a new way. Digital printing reducing waste, enabling short runs, and meeting strict green demands1. Digital printing reduces waste. It enables short runs, on-demand production, and minimal plate usage. This helps brands lower their carbon footprints and stay agile […]

Can Digital Printing Lower Costs and Boost Efficiency in FMCG Packaging?

FMCG brands face fierce competition. Many struggle to stand out on store shelves. They want cost savings. They feel uncertain about old printing methods. This problem needs a solution. Yes. Digital printing can lower costs and boost speed. FMCG companies benefit from short runs, reduced setup fees, and minimized waste. Real-time design changes help prevent […]

How Can I Identify Potential Customers in Different FMCG Segments?

Identifying potential customers in FMCG is important but can be difficult. Digital printing offers a way to help brands connect with the right audience. By customizing packaging, brands can meet the needs of specific groups. Market segmentation by behavior, loyalty, and demographics is crucial in FMCG. Digital printing allows brands to tailor packaging for each […]

What Will the Future of FMCG Packaging Look Like?

The future of FMCG packaging is changing fast. New technologies and consumer preferences are driving this change. What will packaging look like in the years ahead? Let’s explore. FMCG packaging’s future will be driven by digital printing, sustainability, and personalized packaging, enabling brands to differentiate and engage consumers in new ways. To understand where FMCG […]